Research

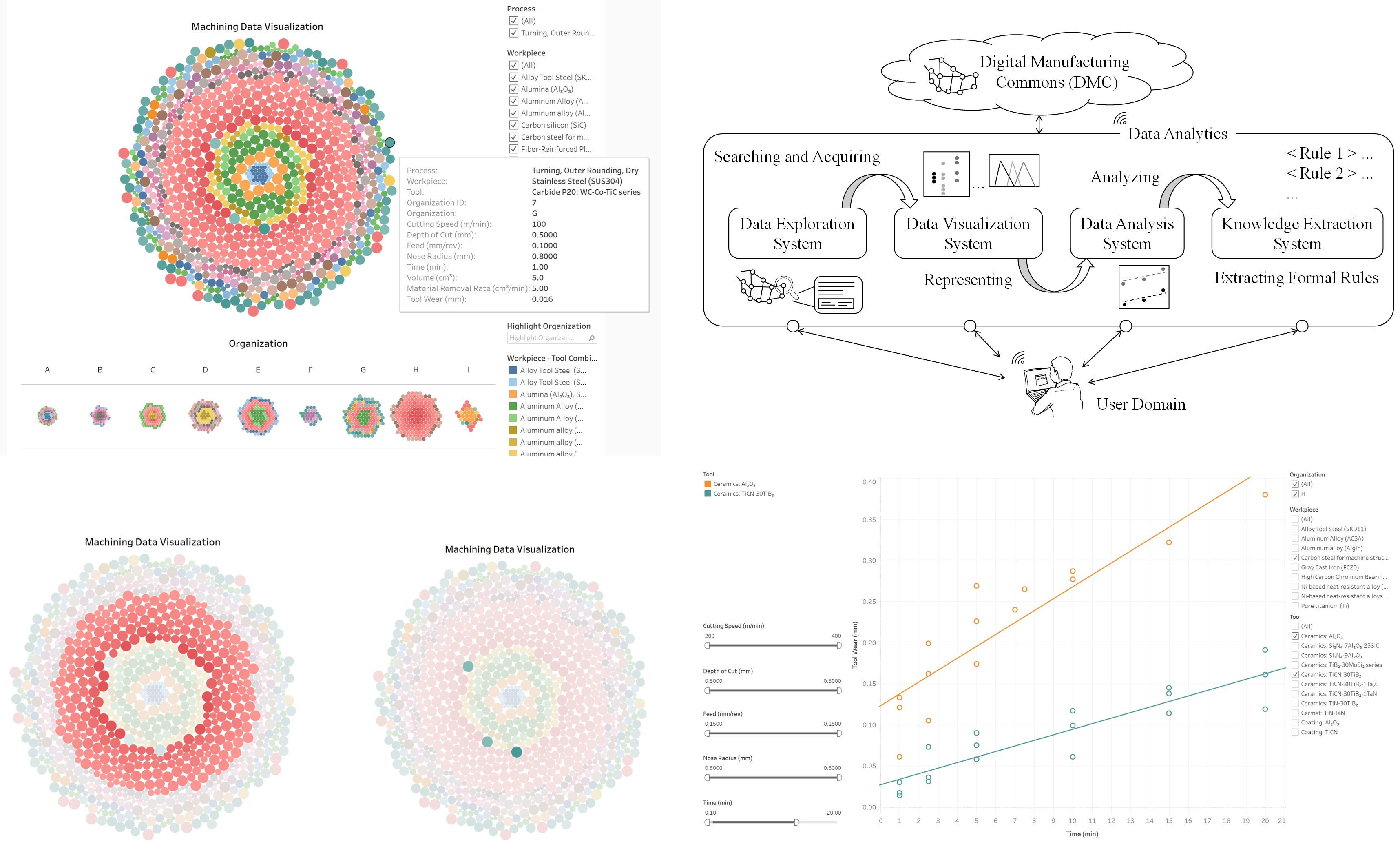

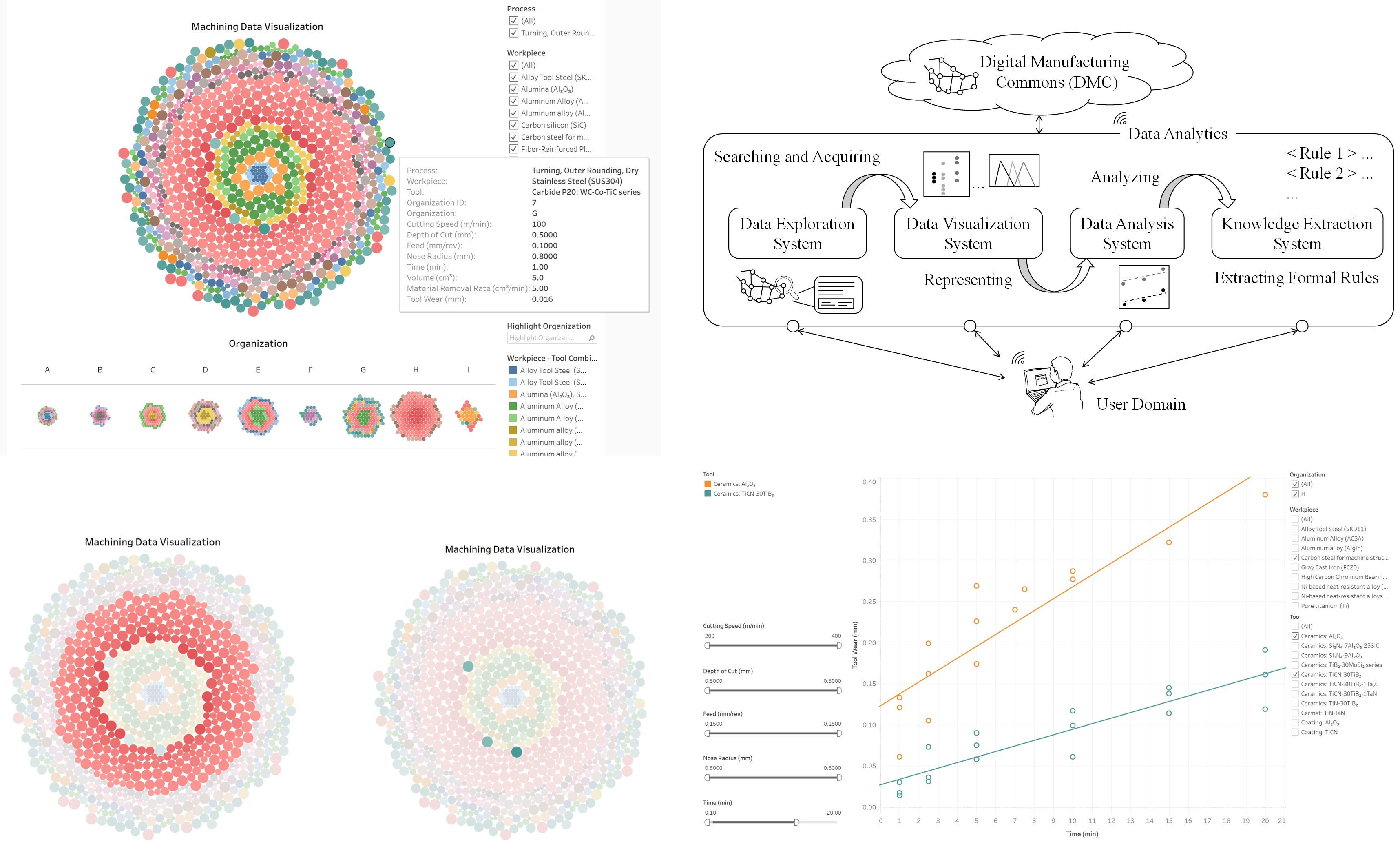

- Big Data Inequality and Digital Manufacturing Commons

Big data analytics, an essential constituent of smart manufacturing, fuels decision-making by extracting knowledge underlying big data. However, developing manufacturing big data and relevant analytics has challenges, such as mitigating big data inequality, mitigating black box syndrome, and ingesting externally generated data. Fulfilling these challenges is essential for supporting SMEs, making the systems feasible for real-life manufacturing practices, avoiding biases while analyzing the BD, and promoting innovation. Our research team @ KIT is working on these issues based on the concept of digital manufacturing commons (DMC) to construct widely accessible manufacturing big data and relevant analytics. We are also researching for a less resource-dependent, computationally light, transparent, and more human-engaging systems architecture.

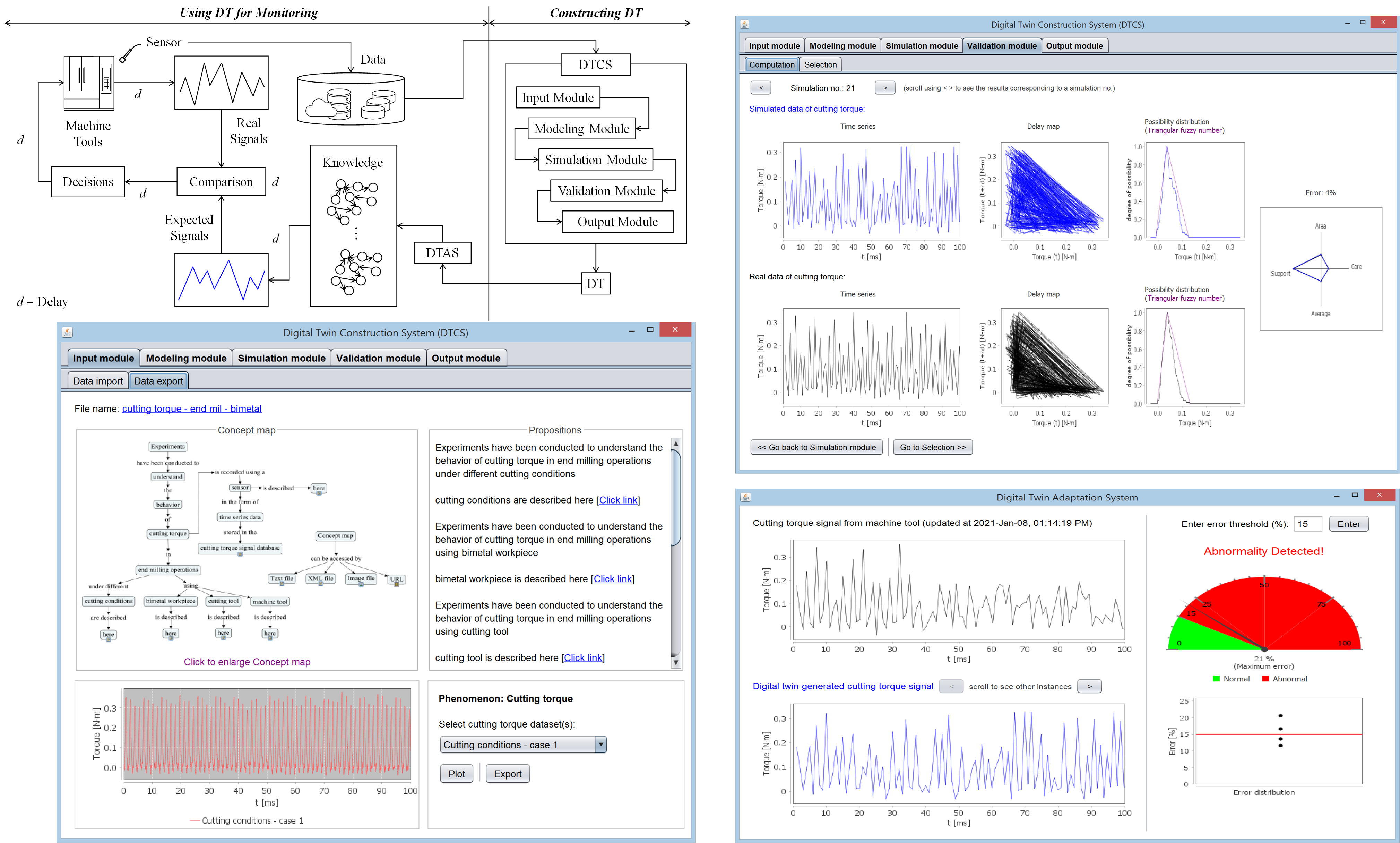

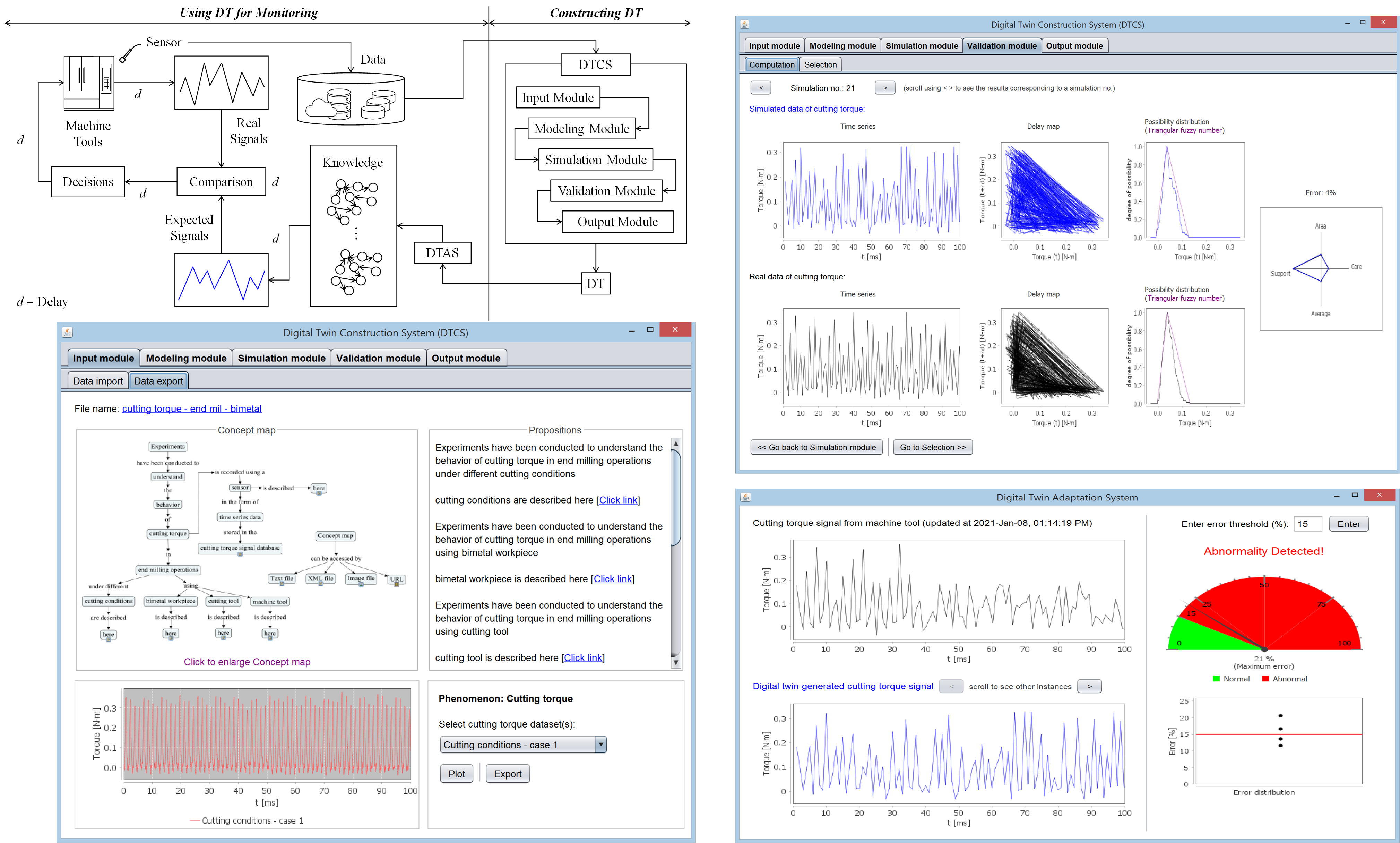

- Sensor Signal-based Digital Twins

Digital twins (Object, Process, and Phenomenon twins) are needed for virtualizing a real-life manufacturing process and functionalizing high-level cognitive tasks (monitoring, understanding, predicting, decision-making, and adapting). Our research team @ KIT is working on developing phenomena twins, using historic phenomena-relevant sensor signal datasets (e.g., cutting force, cutting torque, and alike). Two computerized systems: Digital Twin Construction System (DTCS) and Digital Twin Adaptation System (DTAS), are developed for constructing and adapting the twins, respectfully. The DTCS acquires the relevant datasets from cloud, machine learns the knowledge underlying the datasets, simulates the relevant phenomenon, and validates the simulation outcomes. On the other hand, the DTAS adapts the validated outcomes for real-time monitoring.

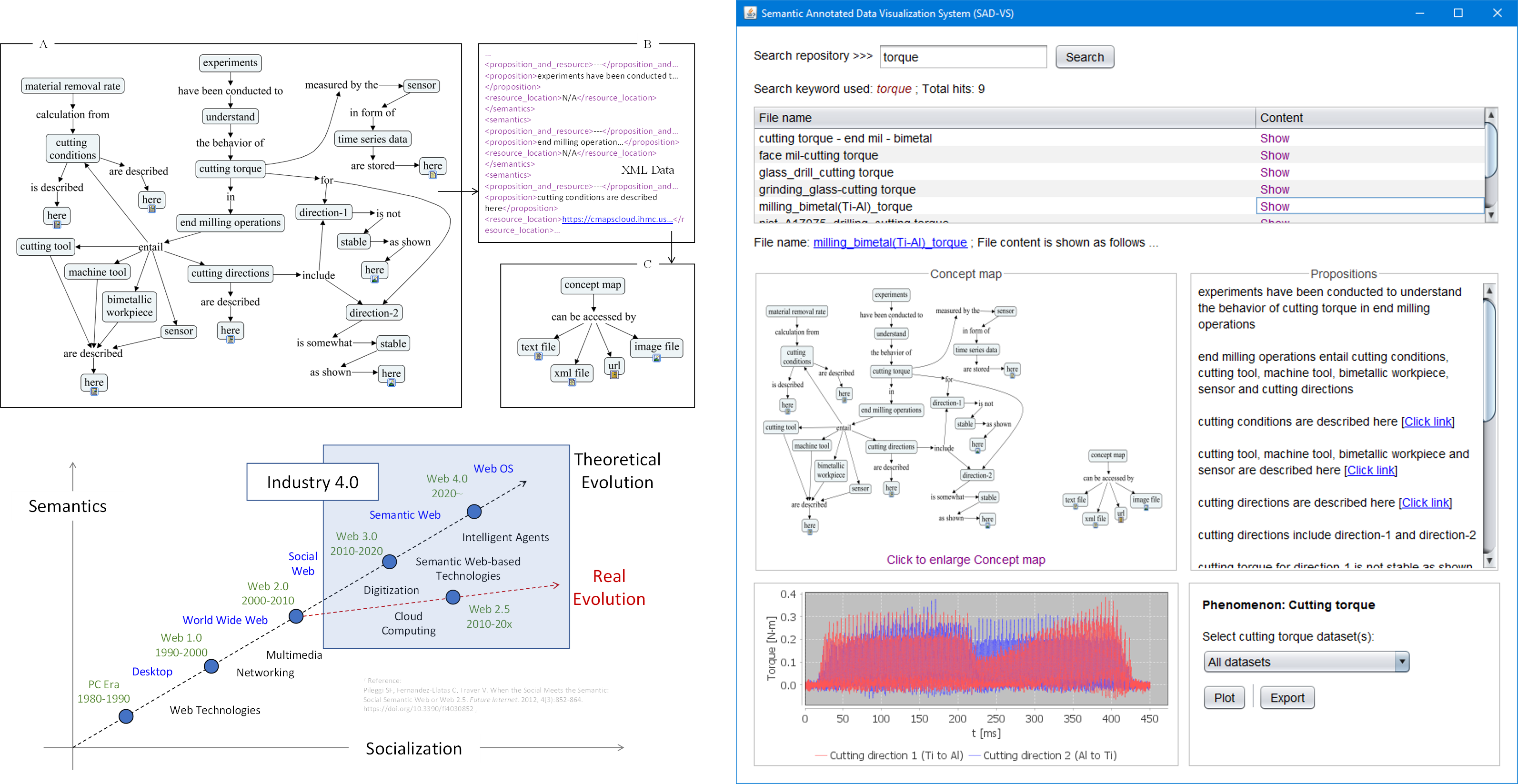

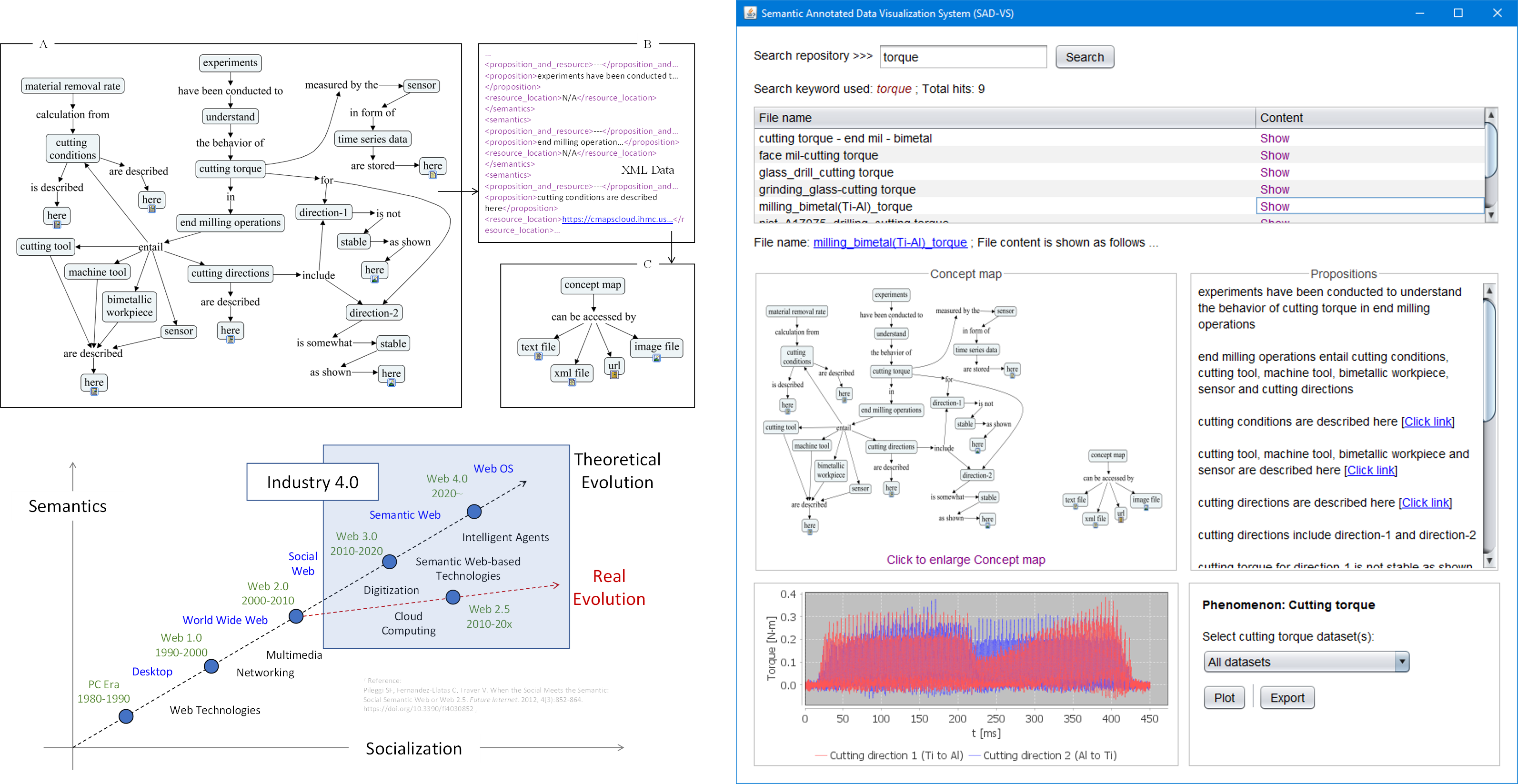

- Semantic Annotation and Knowledge Representation

In smart manufacturing, various manufacturing enablers, such as machine tools, monitoring systems, digital twins, and others, require knowledge to perform high-level cognitive tasks like monitoring, understanding, predicting, decision-making, and adapting. This knowledge is supplied by the ever-growing knowledge-bases in human-cyber-physical systems. To be effective, the knowledge in these bases must be human/machine-comprehensible and represented using a scalable ontology-based method. In reality, representation methods are often domain-specific and follow strict ontological formalism. Our research team @ KIT addresses this issue by proposing a semantic annotation-based representation method. This annotation mechanism utilizes knowledge-type-aware concept mapping, allowing for a more versatile approach. As part of our efforts, we have developed a computerized system known as the Semantically Annotated Data Visualization System (SAD-VS). This system ensures both human and machine comprehensibility of the represented knowledge.

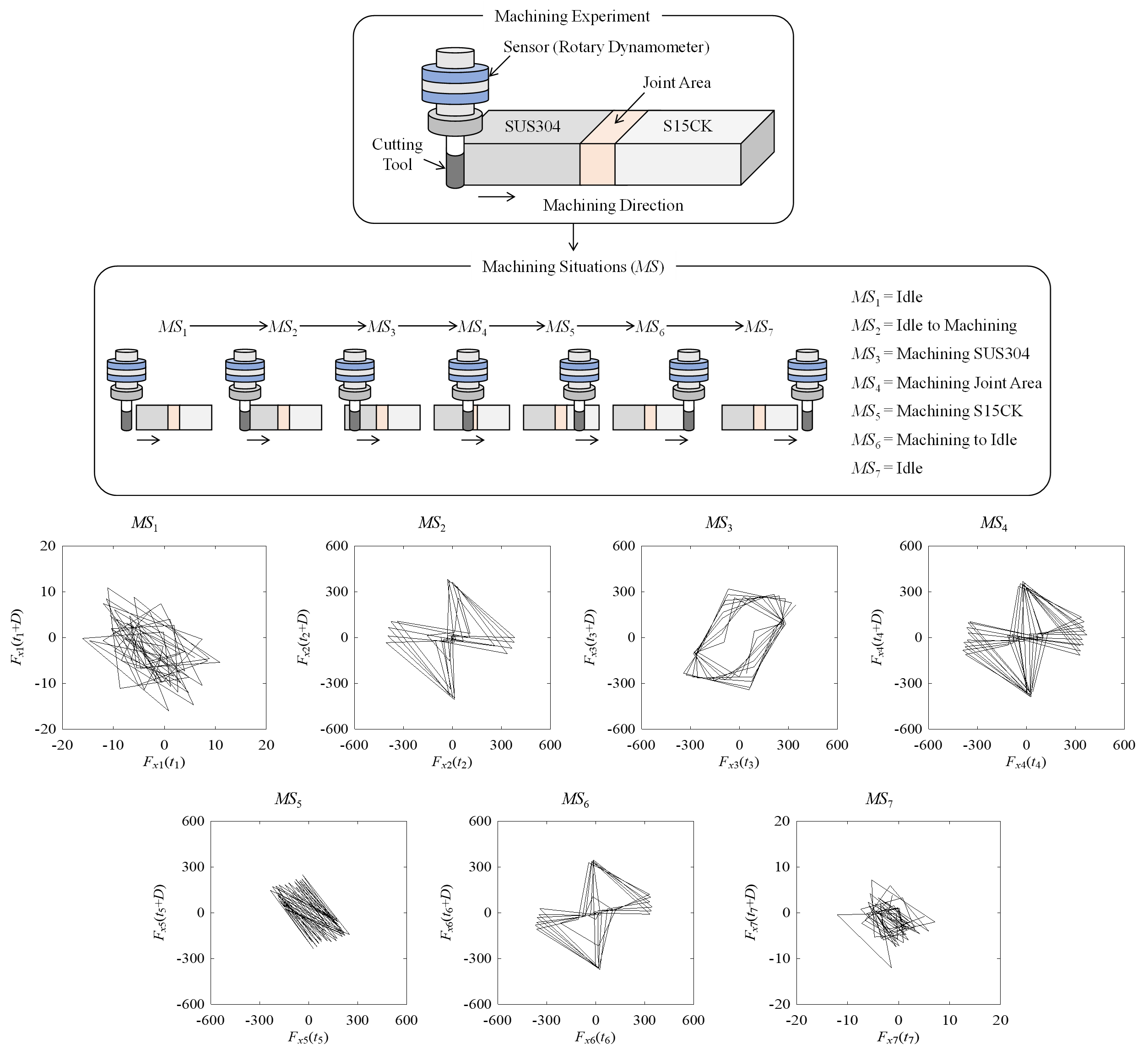

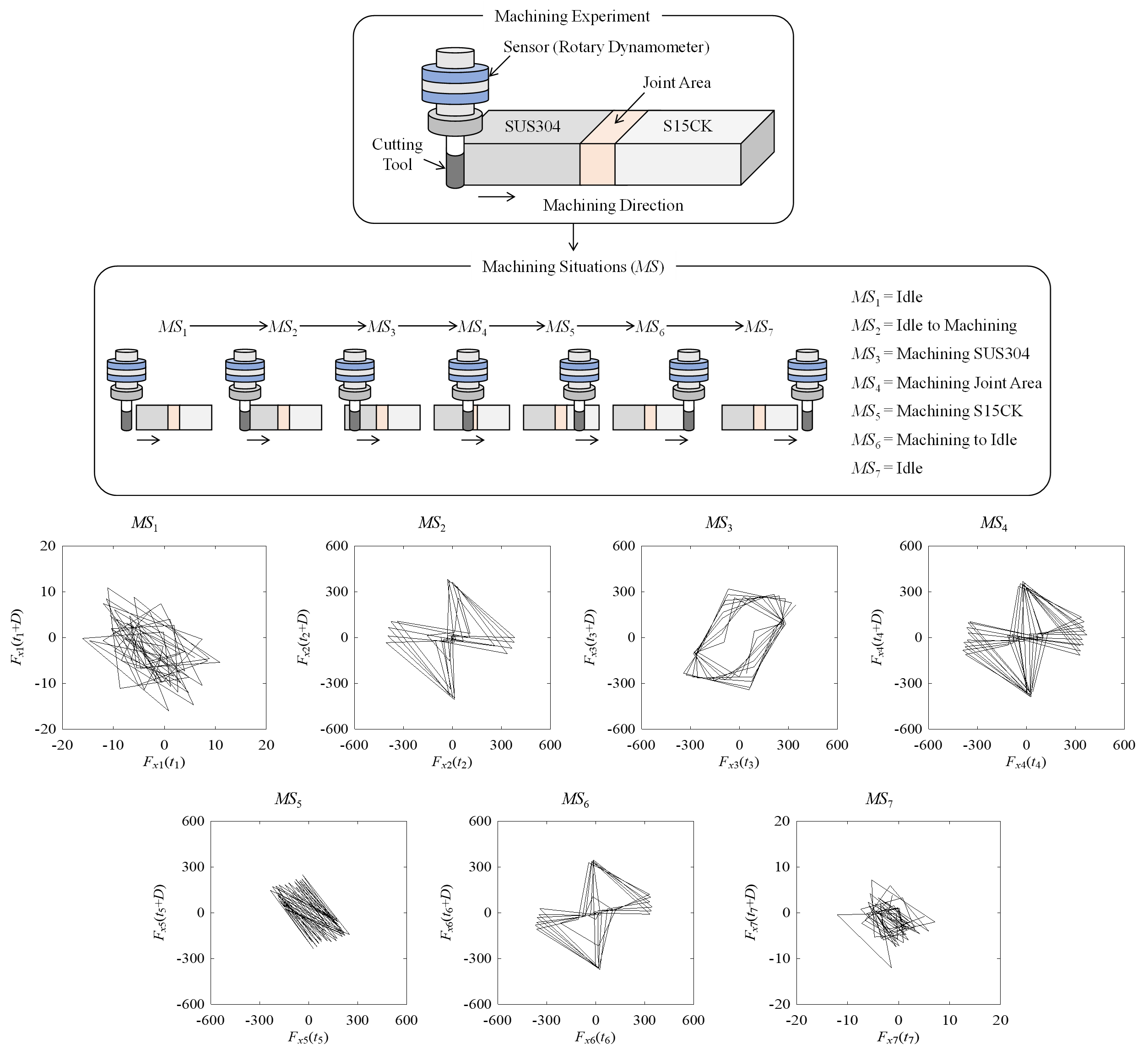

- Signal Processing in Delay Domain

In smart manufacturing, embedded systems such as CNC machine tools, programable logic controllers, digital measuring instruments, cyber-physical systems, and digital twins, collectively perform high-level cognitive tasks (monitoring, understanding, deciding, and adapting) by making sense of sensor signals. When sensor signals are exchanged through the abovementioned embedded systems, a phenomenon called time latency or delay occurs. As a result, the signal at its origin (e.g., machine tools) and signal received at the receiver end (e.g., digital twin) differ. The time and frequency domain-based conventional signal processing cannot adequately address the delay-centric issues. Instead, these issues can be addressed by the delay domain. As such, real-life signals collected while machining different materials are analyzed using frequency and delay domains to reconfirm its (the delay domain’s) significance in real-life settings. In both cases, it is found that the delay domain is more informative and reliable than the time and frequency domains when the delay is unavoidable. Moreover, the delay domain can act as a signature of a machining situation, distinguishing it (the situation) from others. The findings of this study reveal that computational arrangements enabling delay domain-based signal processing must be enacted to effectively functionalize the smart manufacturing-centric embedded systems.